prohibited.

M.13. Synthetic slings cannot be used where fumes,

vapors, sprays, mists, or liquids of acids or other

corrosives are present. They also are not to be

used to hoist hot material, or be used near a spark

generating process.

M.14. Synthetic slings must be taken out of service if

there are any cuts, snags, tears, punctures, acid or

caustic burns, melting, broken or worn stitching,

or if the internal red warning threads are showing.

M.15. No sling is to be shortened by using a knot or

other makeshift device.

M.16. Make sure the slings or spreaders are long enough

to pick the load at a minimum sling leg angle. The

closer this angle is to vertical, the less strain there

is on each leg.

M.17. Do not make a spreader leg into a choker by

hooking it back to itself. If you must, at least make

the rigging a basket type and attach the hooks to

the steel ring and not to the eye of the spreader

leg. Just remember, doing this will most likely

permanently kink the legs, and reduce their overall

capacity.

BEST MANAGEMENT PRACTICES

M.18. Shackles and hooks must be inspected for wear

and distortion. The rated capacity must be

stamped on the unit, and are not to be exceeded.

M.19. Loads must be applied to the hook in the throat

area with the safety latch closed. Hooks must have

a safety latch in place, unless the hook is designed

to be used without one, such as a shakeout or

sorting hook. Tip loading of a hook is extremely

dangerous.

M.20. Overhaul (headache) ball swivels have rated

capacities. These are found on a tag or are

stamped into the unit. As with all rigging, this

rated load must not be exceeded. They too must

be inspected for wear and distortion and in

addition, be maintained and lubricated.

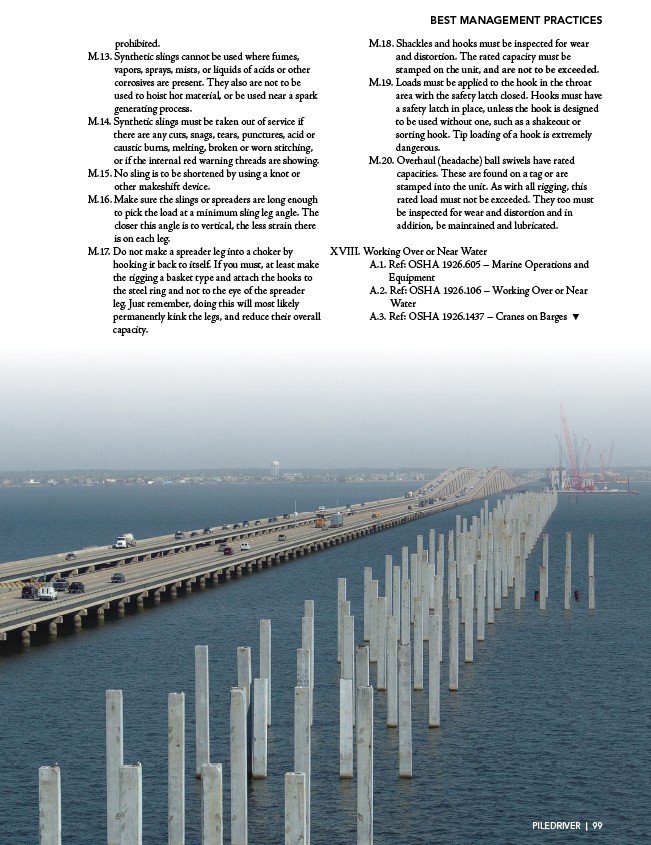

XVIII. Working Over or Near Water

A.1. Ref: OSHA 1926.605 – Marine Operations and

Equipment

A.2. Ref: OSHA 1926.106 – Working Over or Near

Water

A.3. Ref: OSHA 1926.1437 – Cranes on Barges t

PILEDRIVER | 99