Meeting the Challenges

of a Difficult Job

LH Bolduc and American Engineering Testing, Inc. worked together to

tackle the Wayzata Bay redevelopment project

By William Cody and Greg Reuter

This 14-acre site had always been a highly desirable property

due to its proximity to Lake Minnetonka and location

within the City of Wayzata, Minn. However, the site’s

settlement and high maintenance history, due to extensive depths of

highly compressible soils, had blighted previous developments and

scared away redevelopment interests. Teams comprised of investors,

general contractors, architects and engineers came up with redevelopment

concepts in recent years, only to be discouraged when they

realized the likelihood of high initial foundation costs and the risk of

long term problems from “sinking soils.” To overcome this perception,

LH Bolduc and American Engineering Testing (AET) were instrumental

in conveying the value of a pre-design test pile program. We

believe the information from this program (18 pipe piles driven to

various depths in three different areas of the site, dynamically monitored

on restrike over a period of several weeks after initial driving)

and the value engineering initiative that ensued, helped quantify the

risk and brought foundation costs for buildings and infrastructure

into the realm of “economically feasible,” permitting a redevelopment

plan that would finally move forward to a successful completion.

PROJECT SPOTLIGHT

Innovative ideas

To get up and running, just the first phase of the project would

require installation of nearly 1,500 piles, averaging 115 feet in

length. The construction schedule dictated the need for at least

three pile driving rigs – the first rig drove the base section and

spliced the add-on, while the other two rigs performed the final

driving. Four different sized Delmag hammers were used, where

each hammer was used depending on the driving characteristics

and design capacity.

Because we were committed to save pile length and cost, piles

were allowed to set up and capacity determinations were based on

restrike behavior rather than an all-inclusive end of initial drive

blow count and stroke. Driving criteria was developed, based on the

desired pile capacity, pile size, hammer size/energy and subsurface

conditions.

The steel pipe pile selected had to be robust enough to stand up

to occasional debris in the upper fill soils and cobbles and boulders

that can frequent the native glacial deposits at bearing depths. It also

had to be readily available and cost effective. We also wanted a pile

Continued on page 99

Photos courtesy of LH Bolduc and American Engineering Testing

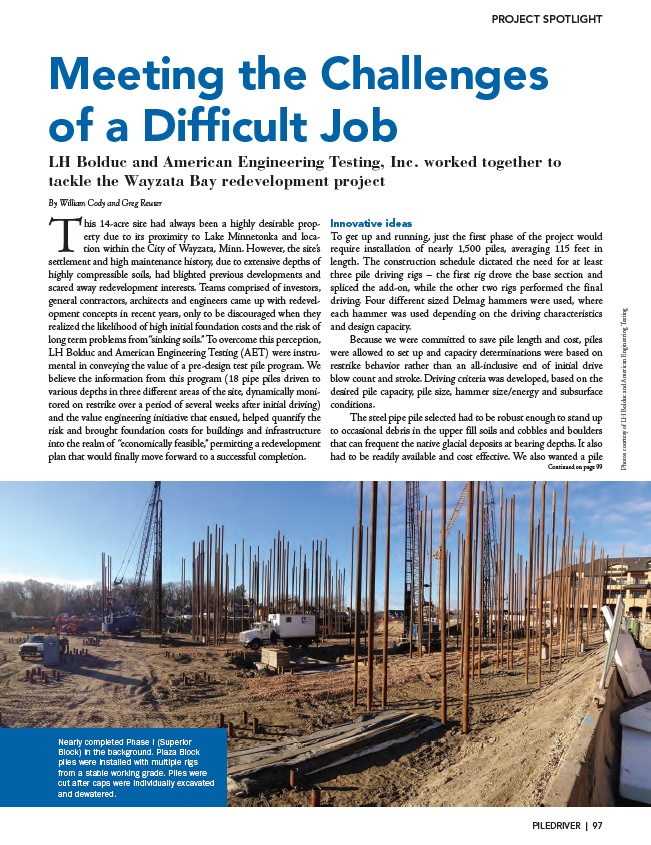

Nearly completed Phase I (Superior

Block) in the background. Plaza Block

piles were installed with multiple rigs

from a stable working grade. Piles were

cut after caps were individually excavated

and dewatered.

PILEDRIVER | 97