MEMBER PROFILE – ASSOCIATE

PVE Seeks to Increase

its U.S. Presence

Dutch-based PVE has long been associated with quality piling

products in Europe, and is now looking to increase its presence in

the U.S. marketplace

By Jim Timlick

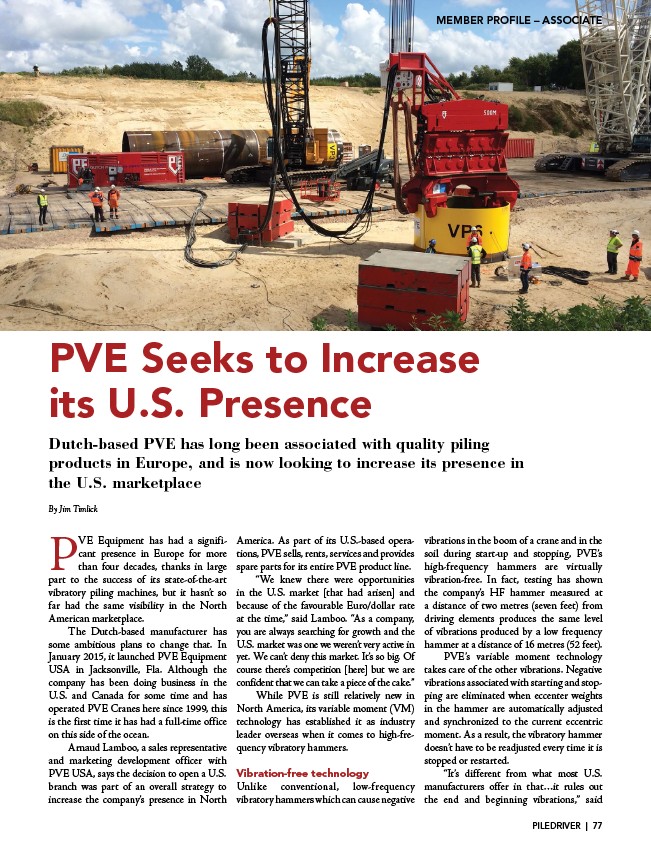

PVE Equipment has had a significant

presence in Europe for more

than four decades, thanks in large

part to the success of its state-of-the-art

vibratory piling machines, but it hasn’t so

far had the same visibility in the North

American marketplace.

The Dutch-based manufacturer has

some ambitious plans to change that. In

January 2015, it launched PVE Equipment

USA in Jacksonville, Fla. Although the

company has been doing business in the

U.S. and Canada for some time and has

operated PVE Cranes here since 1999, this

is the first time it has had a full-time office

on this side of the ocean.

Arnaud Lamboo, a sales representative

and marketing development officer with

PVE USA, says the decision to open a U.S.

branch was part of an overall strategy to

increase the company’s presence in North

America. As part of its U.S.-based operations,

PVE sells, rents, services and provides

spare parts for its entire PVE product line.

“We knew there were opportunities

in the U.S. market that had arisen and

because of the favourable Euro/dollar rate

at the time,” said Lamboo. “As a company,

you are always searching for growth and the

U.S. market was one we weren’t very active in

yet. We can’t deny this market. It’s so big. Of

course there’s competition here but we are

confident that we can take a piece of the cake.”

While PVE is still relatively new in

North America, its variable moment (VM)

technology has established it as industry

leader overseas when it comes to high-frequency

vibratory hammers.

Vibration-free technology

Unlike conventional, low-frequency

vibratory hammers which can cause negative

vibrations in the boom of a crane and in the

soil during start-up and stopping, PVE’s

high-frequency hammers are virtually

vibration-free. In fact, testing has shown

the company’s HF hammer measured at

a distance of two metres (seven feet) from

driving elements produces the same level

of vibrations produced by a low frequency

hammer at a distance of 16 metres (52 feet).

PVE’s variable moment technology

takes care of the other vibrations. Negative

vibrations associated with starting and stopping

are eliminated when eccenter weights

in the hammer are automatically adjusted

and synchronized to the current eccentric

moment. As a result, the vibratory hammer

doesn’t have to be readjusted every time it is

stopped or restarted.

“It’s different from what most U.S.

manufacturers offer in that…it rules out

the end and beginning vibrations,” said

PILEDRIVER | 77