prior to ground improvement. Four “cells”

designated by column and row headings

(e.g., B3, C3) in the middle of each pile

group were selected to represent a theoretically

uniform level of ground improvement

within the pile group. Table 1 indicates

the average number of days that the CPT

soundings were performed following pile

installation and the cell locations corresponding

to Figures 3 and 4. Sounding A

was pushed first in each cell and represents

the midpoint between piles (and therefore

the lowest expected quantity of densification)

so as to compare to the initial improvement

without the possible effects of the

FEATURE

Drained timber piles and PVDs used in this study

Location of CPT’s following timber pile installation.

Figure 2. Drained timber piles and PVDs used in this study

Table 1. Location of CPT’s following timber pile installation.

Figure 2. Drained timber piles and PVDs used in this study

Table 1. Location of CPT’s following timber pile installation.

Figure 2. Drained timber piles and used in this study

Time Following

Installation Cell Locations

(Zones 1 through 4) Cell Locations

10 days B2 B3 and E1

49 days B3 B4 and E2

115 days C2 C3 and F1

255 days C3 C4 and F2

Installation Cell Locations

Following Installation Cell Locations

Time Following Installation Cell Locations

(Zones 1 through 4)

CPT-induced densification on neighboring

soundings (e.g., soundings B and C; see

Figure 5). Focusing on the data obtained

from sounding A in each cell for simplicity,

Figure 6 presents the pre-improvement

baseline, the post improvement at 49 days,

and the predicted post-improvement Dr.

Cell Locations

(Zones 5A and 5B)

(Zones 1 through 4)

The Dr improved to approximately 70

10 days B2 B2 B3 and E1

B3 and E1

49 days B3 B3 B4 and E2

B4 and E2

115 days Table 1. Location of CPTs C2 following timber pile installation

C2 C3 and F1

C3 and F1

255 days C3 C3 C4 and F2

C4 and F2

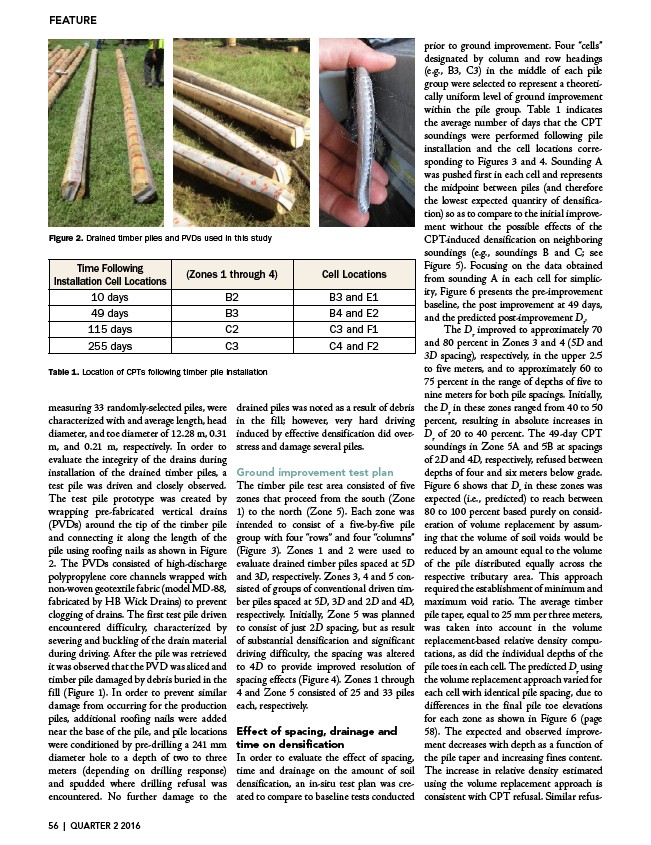

measuring 33 randomly-selected piles, were

characterized with and average length, head

diameter, and toe diameter of 12.28 m, 0.31

m, and 0.21 m, respectively. In order to

evaluate the integrity of the drains during

installation of the drained timber piles, a

test pile was driven and closely observed.

The test pile prototype was created by

wrapping pre-fabricated vertical drains

(PVDs) around the tip of the timber pile

and connecting it along the length of the

pile using roofing nails as shown in Figure

2. The PVDs consisted of high-discharge

polypropylene core channels wrapped with

non-woven geotextile fabric (model MD-88,

fabricated by HB Wick Drains) to prevent

clogging of drains. The first test pile driven

encountered difficulty, characterized by

severing and buckling of the drain material

during driving. After the pile was retrieved

it was observed that the PVD was sliced and

timber pile damaged by debris buried in the

fill (Figure 1). In order to prevent similar

damage from occurring for the production

piles, additional roofing nails were added

near the base of the pile, and pile locations

were conditioned by pre-drilling a 241 mm

diameter hole to a depth of two to three

meters (depending on drilling response)

and spudded where drilling refusal was

encountered. No further damage to the

Cell Locations

(Zones 5A and 5B)

(Zones 1 through 4)

drained piles was noted as a result of debris

in the fill; however, very hard driving

induced by effective densification did overstress

and 80 percent in Zones 3 and 4 (5D and

3D spacing), respectively, in the upper 2.5

to five meters, and to approximately 60 to

75 percent in the range of depths of five to

nine meters for both pile spacings. Initially,

the Dr in these zones ranged from 40 to 50

percent, resulting in absolute increases in

Dr of 20 to 40 percent. The 49-day CPT

soundings in Zone 5A and 5B at spacings

of 2D and 4D, respectively, refused between

depths of four and six meters below grade.

Figure 6 shows that Dr in these zones was

expected (i.e., predicted) to reach between

80 to 100 percent based purely on consideration

1

1

and damage several piles.

5

B

Ground improvement test plan

The timber pile test area consisted of five

zones that proceed from the south C

(Zone

A

1) to the north (Zone 5). Each zone was

intended to consist of a five-by-five pile

of volume replacement by assuming

group with four “rows” and four 9 “columns”

4

that the volume of soil voids would be

(Figure 3). Zones 1 and 2 were used to

reduced by an amount equal to the volume

evaluate drained timber piles spaced at 5D

of the pile distributed equally across the

and 3D, respectively. Zones 3, 4 and 5 consisted

respective tributary area. This approach

of groups of conventional driven timber

required the establishment of minimum and

piles spaced at 5D, 3D and 2D and 4D,

maximum void ratio. The average timber

respectively. Initially, Zone 5 was planned

pile taper, equal to 25 mm per three meters,

to consist of just 2D spacing, but as result

was taken into account in the volume

of substantial densification and significant

replacement-based relative driving difficulty, the spacing was altered

sketch density computations,

of cell B2 to 4D to provide improved resolution of

Zones 1 through spacing effects (Figure 4). Zones 1 through

4 and Zone 5 consisted of 25 and 33 piles

of 5 to 9 m for both pile spacings.each, respectively.

Initially, the Dr in these zones ranged from 40 to 50%,resulting in absolute increases in Effect Dr of of spacing,20 to drainage 40%.and

The 49-day CPT soundings in Zone and 5B at spacings of 2D and 4D,time on densification

In order respectively,to evaluate the effect refused of spacing,

between depths of 4 and 6 m below

grade. Figure 6 shows that Dr in time these and drainage zones on the was amount expected of soil

(i.e., predicted) to reach between

80 to 100% based purely on consideration densification, an in-situ of test plan volume was created

replacement by assuming that volume of soil voids would be reduced by an amount equal to the volume of the distributed equally across the respective tributary area. This approach required plan

Figure 4. In-situ test plan for Zone 5 Figure 5. Enlarged

sketch of cell B2 in

Zones 1 through 4

as did the individual depths of the

pile toes in each cell. The predicted Dr using

the volume replacement approach varied for

each cell with identical pile spacing, due to

differences in the final pile toe elevations

for each zone as shown in Figure 6 (page

58). The expected and observed improvement

spacings. Initially, the Dr in these zones ranged from 40 to 50%,

increases in Dr of 20 to 40%. The 49-day CPT soundings in Zone 5A

decreases with depth as a function of

4D, respectively,refused between depths of 4 and 6 m below

the pile taper and increasing fines content.

The increase in relative density estimated

using the volume replacement approach is

consistent with CPT refusal. Similar refus-

that Dr in these zones was expected (i.e., predicted) to reach between

purely on consideration of volume replacement to compare to baseline by tests assuming conducted

that the

would be reduced by an amount equal to the volume of the pile

across the respective tributary area. This approach required the

Cell Locations

(Zones 5A and 5B)

10 days B2 B3 and E1

49 days B3 B4 and E2

115 days C2 C3 and F1

255 days C3 C4 and F2

Figure 3. In-situ test plan

for Zones 1 through 4

5

C

B

A

9 4

1

5

C

B

A

9 4

Figure 4. In-situ test plan for Zone 5 Figure 5. Enlarged

In-situ test plan

Zones 1 through 4

Figure 4. In-situ test plan for Zone 5 Figure 5. Enlarged

sketch of cell B2 in

Zones 1 through 4

for both pile spacings. Initially, the Dr in these zones ranged from 40 to 50%,

absolute increases in Dr of 20 to 40%. The 49-day CPT soundings in Zone 5A

spacings of 2D and 4D, respectively,refused between depths of 4 and 6 m below

Figure 6 shows that Dr in these zones was expected (i.e., predicted) to reach between

based purely on consideration of volume replacement by assuming that the

soil voids would be reduced by an amount equal to the volume of the pile

equally 56 across | QUARTER 2 the 2016

respective tributary area. This approach required the