INTERNATIONAL

successful with several major infrastructure projects in Peru and

Ecuador from major roadways, bridges, drainage and commercial

building construction.

Numerous challenges

The challenges on a project of this magnitude have been plentiful

for the team and primarily consist of three main issues:

•• A remote project location with the closest airport more than

three hours away through winding, single-lane roadways

•• A prolonged rainy season that lasts the majority of the year.

Crews must deal with water-saturated ground conditions,

landslides and occasional river floods.

•• An environmentally sensitive area with plenty of wildlife

Pareja says access to the project site has been difficult with

the transportation of heavy equipment and construction supplies a

constant challenge. Makeshift platforms (steel road plates, timber

matts, etc.) have been built on the winding access roadways.

“The contractor built a steel/mechanic shop facility onsite in

order to stock the required equipment to fabricate ‘in-house’ many

of the steel components used for the pile templates, insert modifications,

temporary pile caps, etc.,” he said. “Also, during the heavy

rainy seasons – besides the normal impact on production that a

prolonged rainy season has on any project site – the contractor had

to constantly monitor the water level of the adjacent river and take

necessary precautions against floods.”

In addition, the working radius for the cranes was constantly

changing due to shifting water levels. Operators and managers

constantly check load charts before continuing with any piling

operations.

“Having a unit stuck in the mud is a normal occurrence,”

said Pareja. “The fact that the cranes available to the contractor

are wheel-mounted and not crawler type becomes a real problem,

Photos courtesy of ICE® – International Construction Equipment, Inc.

EQUIPMENT SNAPSHOT

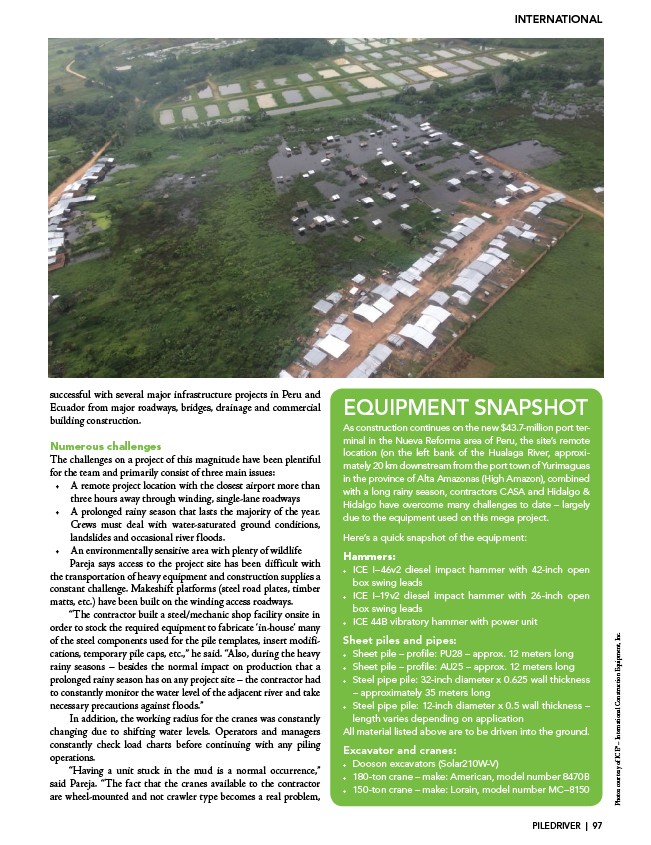

As construction continues on the new $43.7-million port terminal

in the Nueva Reforma area of Peru, the site’s remote

location (on the left bank of the Hualaga River, approximately

20 km downstream from the port town of Yurimaguas

in the province of Alta Amazonas (High Amazon), combined

with a long rainy season, contractors CASA and Hidalgo &

Hidalgo have overcome many challenges to date – largely

due to the equipment used on this mega project.

Here’s a quick snapshot of the equipment:

Hammers:

•• ICE I–46v2 diesel impact hammer with 42-inch open

box swing leads

•• ICE I–19v2 diesel impact hammer with 26-inch open

box swing leads

•• ICE 44B vibratory hammer with power unit

Sheet piles and pipes:

•• Sheet pile – profile: PU28 – approx. 12 meters long

•• Sheet pile – profile: AU25 – approx. 12 meters long

•• Steel pipe pile: 32-inch diameter x 0.625 wall thickness

– approximately 35 meters long

•• Steel pipe pile: 12-inch diameter x 0.5 wall thickness –

length varies depending on application

All material listed above are to be driven into the ground.

Excavator and cranes:

•• Dooson excavators (Solar210W-V)

•• 180-ton crane – make: American, model number 8470B

•• 150-ton crane – make: Lorain, model number MC–8150

PILEDRIVER | 97